-

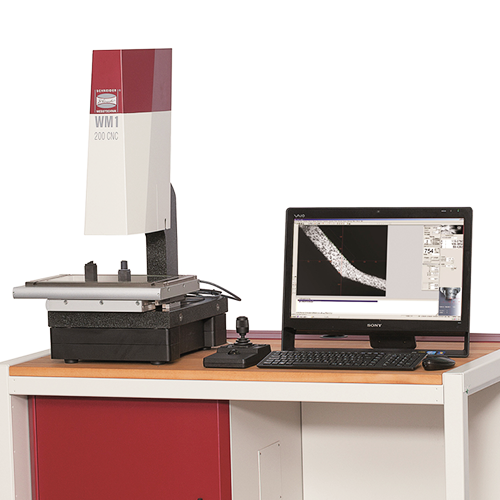

Workshop microscopes from the WM1 Series – Manual or CNC version of the WM1 – our two measurement software packages, SAPHIR and M3. In the entry-level class, the M3 measurement software sets standards in intuitive operation and functionality. Should you have further demands on the programming and analysis possibilities, then our 3D measurement software is available here. Both software packages can be optionally upgraded in the CNC version with a tactile measuring probe to form a "small" multisensor device. The WM1 Series offers tailored solutions that can be flexibly adapted to your needs and tailored to your budget.

Workshop microscopes from the WM1 Series – Manual or CNC version of the WM1 – our two measurement software packages, SAPHIR and M3. In the entry-level class, the M3 measurement software sets standards in intuitive operation and functionality. Should you have further demands on the programming and analysis possibilities, then our 3D measurement software is available here. Both software packages can be optionally upgraded in the CNC version with a tactile measuring probe to form a "small" multisensor device. The WM1 Series offers tailored solutions that can be flexibly adapted to your needs and tailored to your budget. -

Measurements don’t get much quicker or simpler than this. Choose the single-image field system of the V-CAD 60 (this covers a measuring range of up to 65 x 55 mm, without table movement), or the larger variant with moving table (V-CAD 300) and measuring volume of up to 300 x 200 mm that can alternatively also be used in fully automated CNC mode. Here you have a whole host of options when it comes to your 2D measurements. Decades of experience in building high-precision multi-sensor measuring machines have been incorporated into the developing and production of the V-CAD Series. You can count on us – Made by Schneider Messtechnik – Made in Germany – SIMPLY PRECISE!

Measurements don’t get much quicker or simpler than this. Choose the single-image field system of the V-CAD 60 (this covers a measuring range of up to 65 x 55 mm, without table movement), or the larger variant with moving table (V-CAD 300) and measuring volume of up to 300 x 200 mm that can alternatively also be used in fully automated CNC mode. Here you have a whole host of options when it comes to your 2D measurements. Decades of experience in building high-precision multi-sensor measuring machines have been incorporated into the developing and production of the V-CAD Series. You can count on us – Made by Schneider Messtechnik – Made in Germany – SIMPLY PRECISE! -

The new digital projector from Schneider Messtechnik combines the benefits of the proven projector with digital image processing. Simply upload your DXF file to the screen and place it precisely over your workpiece. Once aligned with the workpiece, the drawing moves synchronously with the table movements so that you have the appropriate drawing detail available at all times. But the defining of circles, lines, angle and much, much more at the device also contributes to fast working with the device. And of course we have also integrated corresponding aids that support you in clear edge detection.

The new digital projector from Schneider Messtechnik combines the benefits of the proven projector with digital image processing. Simply upload your DXF file to the screen and place it precisely over your workpiece. Once aligned with the workpiece, the drawing moves synchronously with the table movements so that you have the appropriate drawing detail available at all times. But the defining of circles, lines, angle and much, much more at the device also contributes to fast working with the device. And of course we have also integrated corresponding aids that support you in clear edge detection. -

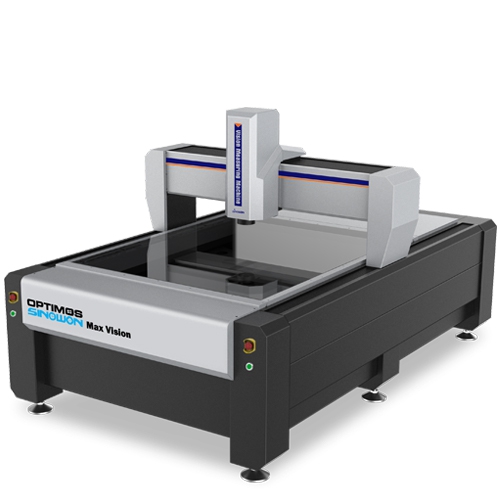

- Model Auto-Vision / Auto-Touch / Auto-Scan

- Moving gantry structure, measurement work piece is fixed;

- Four-axis CNC fully auto close loop control, auto measurement

- “00” grade “JINANQING”marble base and pillar, stable and reliable;

- Imported open type linear scale, resolution is 0.1um, high accuracy, great stability;

- Imported P grade linear guide,, precision grinding ball screw and AC servo motor, ensure accuracy stability of system position;

- Imported high definition color industry camera, ensure clear observation and stable measurement requirement;

- 6.5X continue auto zoom lens, precision auto zoom, only need to make pixel calibration once time;

- Programmable 5-ring 8-division LED surface illumination, contour parallel LED illumination, can realize 256 grade brightness adjustment intelligently;

- With imported non-contact laser sensor, realize thickness and flatness and other measurement;

- With proprietary fully auto measuring software iMeasuring 4.4, powerful function, simple operation;

- Touch probe and laser probe, it can also be customized according to customer request;

- Optional FexQMS Measuring Data Analysis and Real-time monitoring software which enhance program control and reduce material consumption.

-

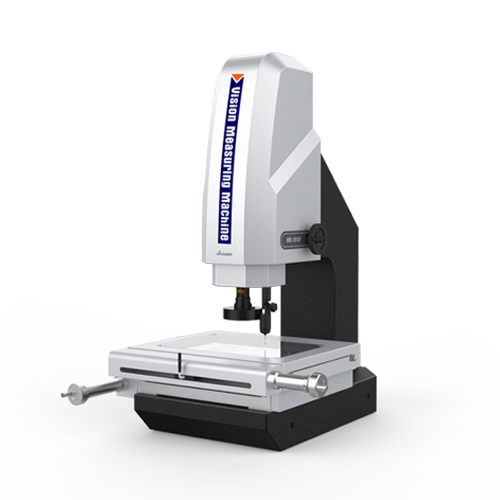

- Model: iTouch / iFocus / iVision

- High precision marble base and pillar ensures the high stability of vision measuring system;

- High precision toothless rod and fast moving locking device ensures repeatability error is less than 2um;

- High precise working stage with 0.5um optical linear scales ensures the accuracy is less than 2.5+L/200um;

- High definitive detent zoom lens and high resolution color camera ensures clear image without distortion;

- With programmable surface 4-ring 8-division LED Cold Illumination and contour LED telecentric illumination and built-in intelligent light adjustment, it can automatic control the brightness in the 4-ring 8-division;

- Z-axis focus is motorized by the DC servo motor and it is adjustable by the software;

- Britain touch trigger probe and powerful function iMeasuring3.1 3D Measuring Software, highly enhance the quality control;

-

- High depth of field, low distortion double telecentric lens, no need to repeat focus.

- Software processes the image by the way of Sub-pixel edge detection and automatic removal of burrs and outliers and the least-square method to ensure accuracy.

- Automatic location and orientation correction, automatically detect and measure based on the recorded shape of the sample, measure with a click of button.

- Automatically identify multiple parts, test elements, then conduct automatic measurement, satisfied with batch measurement requirements.

- Entire image, no need to move the working stage, both high efficiency and high accuracy.

- Improve efficiency, save labor cost, eliminate operator error.

- Automatic memory and output measuring values, and make test data simple applied

-

- Moving gantry structure, measurement workpiece is fixed;

- Four-axis CNC fully auto close loop control, auto measurement;

- “00” grade “JINANQING” marble base and pillar, stable and reliable;

- Important open type linear scale, resolution is 0.0001mm, high accuracy, great stability;

- Imported P grade linear guide, precision grinding ball screw and AC servo motor, ensure accuracy stability of system position;

- Imported high definition color industry camera, ensure clear observation and stable measurement requirement;

- 6.5X continue auto zoom lens, precision auto zoom, only need to make pixel calibration once time;

- Programmable 5-ring 8-division LED surface illumination, contour parallel LED illumination, can realize 256 grade brightness adjustment intelligently;

- With proprietary fully auto measuring software iMeasuring 4.1, powerful function, simple operation;

- Optional laser probe, it can also be customized according to customer request;

- Optional 3D Touch Probe.

-

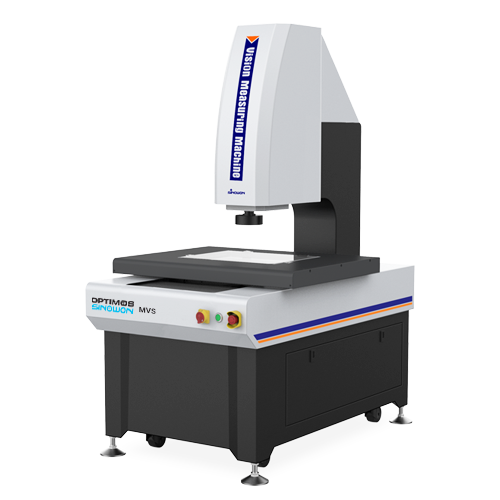

- XYZ three axis CNC automatic control and accurate positioning;

- Granite base and column, excellent stability;

- Precision linear guide, grinding ball screw and AC servo motor etc., to ensure the precision and stability of the motion system;

- 0.5 um high precision glass linear scale to ensure the positioning accuracy and measurement accuracy of the system;

- High resolution color camera to meet the needs of clear observation and accurate measurement;

- 6.5x high-resolution click zoom lens, accurate doubling and one times pixel correction only needed;

- With programmable surface 4-ring 8-division LED Cold Illumination and contour LED parallel illumination and built-in intelligent light adjustment, it can automatic control the brightness in the 8-division;

- Powerful function and easy operation iMeasuring 4.1 Measuring Software to enhance quality control;

- Automatic measurement program can be set to complete batch measurement efficiently and quickly.

-

- It can measure point, line, circle, arc and oval, rectangular with the multipoint positioning function,combination of measurements, center structure and the intersection of structure, the midpoint of construction, line structure, a round structure.

- It has various functions of data processing, display, input and output, Measurement data output Word,Excel and Auto CAD directly to conduct statistical analysis, particularly, and the work piece straightening function is very useful.

- Digital measurement and data processing system are made up by the two coordinate's studio, the optical grating and the SDK -3000 data card.

- It has RS232 interface with a computer and specialized measurement software which can also processes and output circular mapping.

- Macros will be faster and more convenient to measure the same spare parts, for the improvement of measurement efficiency.

-

- Marble base & beam structure, high speed measuring accuracy. UK RENISHAW contact probe ; Laser displacement sensor can measure the thickness of transparent glass and flatness

- Measure point, line, circle, arc and oval, rectangular with the multipoint positioning function,combination of measurements, center structure and the intersection of structure, the midpoint, line structure, a round structure.

- Measurement data output Word,Excel and Auto CAD directly to conduct statistical analysis, particularly, and the work piece straightening function.

- With automatic zoom lens, after finishing automatic zoom no need to manually re-calibration accuracy.

-

- Big travel automatic Video measuring machine use the beam structure, marble base, servo motor and double closed loop.

- Used in three-dimensional work piece on the slope, round, bad ditch, columns, ball, dimension, three-dimensional measurements such as blind holes as well as the distance between the elements, angle and other geometrical terms;

- The machine can test products as below: 1) Machinery: sheet, mould & die, gear, turning parts like bearings ,shaft; 2) Electronics: phone& tablet sheet, PCB, watch parts, etc;

-

Optical Automatic Video Measuring Machine And Equipment For Industry

Optical Automatic Video Measuring Machine And Equipment For Industry- Optical Automatic video measuring machine can measure point, line, circle, arc and oval,rectangular with the multi-point positioning function,combination of measurements, center structure And the intersection of structure, the midpoint of construction, line structure, a round structure.

- It can measure and detect many kinds of complex part's dimension and profile like Template, Stamping parts, Cam,screw thread, gear, forming cutter, terminal, diamond, clock and so on.

- Be Applied to Mechanical ,Electronic ,Instrument.Plastic Fields etc.

- Function of Data Processing,Displaying,Input,Output,

- With Quick Measuring Software.

- Obviously assistant laser position system.Easy to find the measuring position.

- UK Renishaw Probe (Option)

-

- This machine is used in the field of coordinate measurement, especially in machinery, electronic, instrument, plastic fields etc.

- Can quickly find the measured work-piece position and do the measuring.

- With Quick Measuring Software.

- Obviously assistant laser position system.Easy to find the measuring position.

- UK Renishaw Probe (Option)